The uninterrupted use and serviceability of that concrete floor for production are vital to the profitability of.

Concrete floor soil compaction specifications for industry.

A properly prepared subgrade.

A floor system is as good as soil work and any deficiency in it will result in failure through cracks.

To meet the specific service requirements of all your concrete floors.

The concrete floor in any manufacturing or processing industry is the heart of the business.

Compact disturbed soil beneath footings slabs basement floors patios garage floors driveways concrete steps and sidewalks.

Soil compaction compaction is the application of mechanical energy to a soil to rearrange the particles and reduce the void ratio.

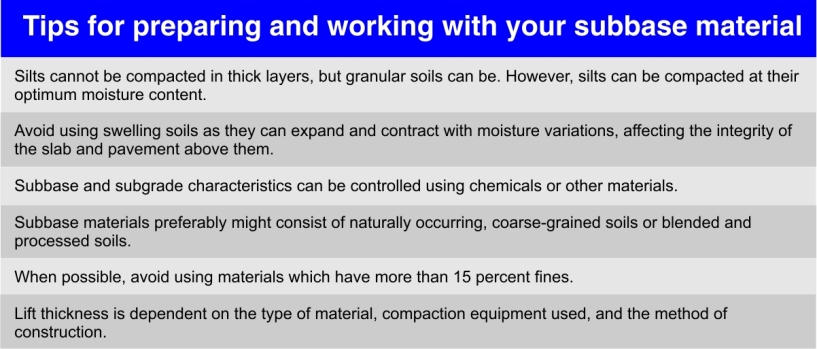

Uniformity in both soil composition and compaction is the key to a good subgrade one that will provide adequate support ensure an even slab thickness and prevent slab settlement and structural cracking.

To get the best compaction the optimal moisture content will typically be in the range of 10 to 20.

Compaction grouting consists of injecting a low slump low mobility silty sand cement grout into loose soils at high pressures.

Common mistakes in concrete floor slab construction can be avoided with proper base preparation mix design placement finishing and curing.

In this article we discuss the construction process thickness and cost of garage floor slab.

Industrial concrete flooring specification guide.

3 1 purpose of compaction the principal reason for compacting soil is to reduce subsequent settlement under working loads.

Quality floor construction includes good subgrade compaction even thickness slabs low slump concrete straight bulkhead lines and control cuts spaced 24 to 30 times the slab thickness.

Compaction increases the shear strength of the soil.

Contents construction of garage floor slab1.

American concrete institute s defines subgrade as the native soil or improved soil usually compacted and sub base is a layer of gravel on top of the subgrade.

So when you hear that according to the specification the soil needs to be at 95 of the maximum modified proctor density you will know that you need the moisture content to be about right in order to get to that level of compaction.

Where is compaction needed.

Garage floor slab construction process includes the preparation of base erection of formwork placement of reinforcement pouring compaction finishing and curing of the concrete slab.

Compaction grouting is a technique for improving both the density and strength of foundation soils.

Slow injection rates are used to limit soil hydro fracture and maintain grout control.

If a sand gravel or crushed stone base is used beneath a slab compact it too.

Soil settling is a primary cause of cracks in a concrete slab.

This has a bearing on the operational efficiency of the floor.