The truth is the first rolling device ever made to measure concrete floor profiles was developed by the face companies in the late 1980s and early 90s.

Concrete floor profiling graph.

The blasted concrete surface is too rough to be measured by tape and quantified in microns or mils.

Large or difficult surfaces will usually be mechanically profiled.

One of the biggest mistakes in gardening is failing to prepare the soil properly by loosening the soil and adding organic matter before planting gardeners can set themselves up for success.

To create a desired concrete surface mechanical and chemical methods are used.

For concrete polymer modified overlays.

The graphs below represent the motion of 5 different objects.

Let us help you sell your used d meters and f meters.

The f meter is the finest floor profiling instrument ever made.

Ideal for testing new large 10 000 sq ft slabs.

Some are graphs of velocity v in the x direction versus time.

With the concrete sound and contaminant free all that s left is to adequately roughen the surface but to what degree.

Mechanical profiling is the method of choice.

Velocity versus time graph of a ball of mass 5 0 g rolling on a concrete floor is shown above.

Pulled manually across the floor the f meter can measure up to 2500 linear feet 5 000 point elevation readings per hour a data collection rate 3 to 5 times faster than any other device.

Claude besson explains the best techniques for concrete profiling.

We ll be adding some more details here soon please check back.

If your organization is interested in retiring some of your floor profiling equipment we might be able to help.

We wanted it to be a quick check profiler for contractors to estimate their ff numbers.

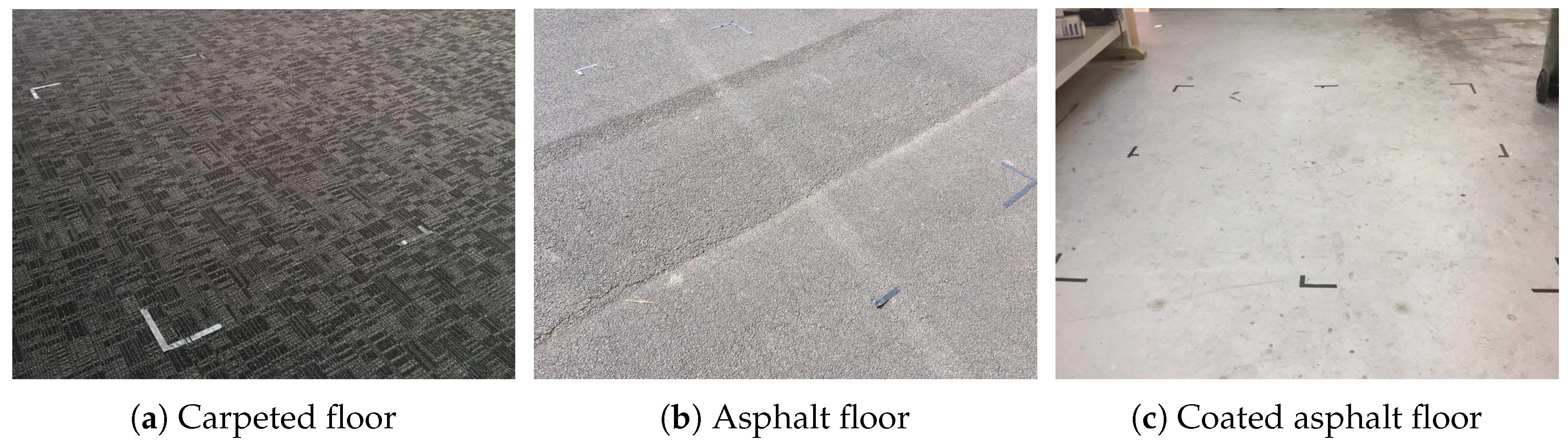

The wood and concrete profiling provided by dustram certified contractors leaves the subfloor clear of dirt protruding staples screws or nails adhesive glues paint spills and even pet stains so it is ready for the brand new flooring the homeowner desires.

Some are graph of position x in the x.

Contractors and manufacturers are split between roughening the concrete by mechanical profiling or acid etching.

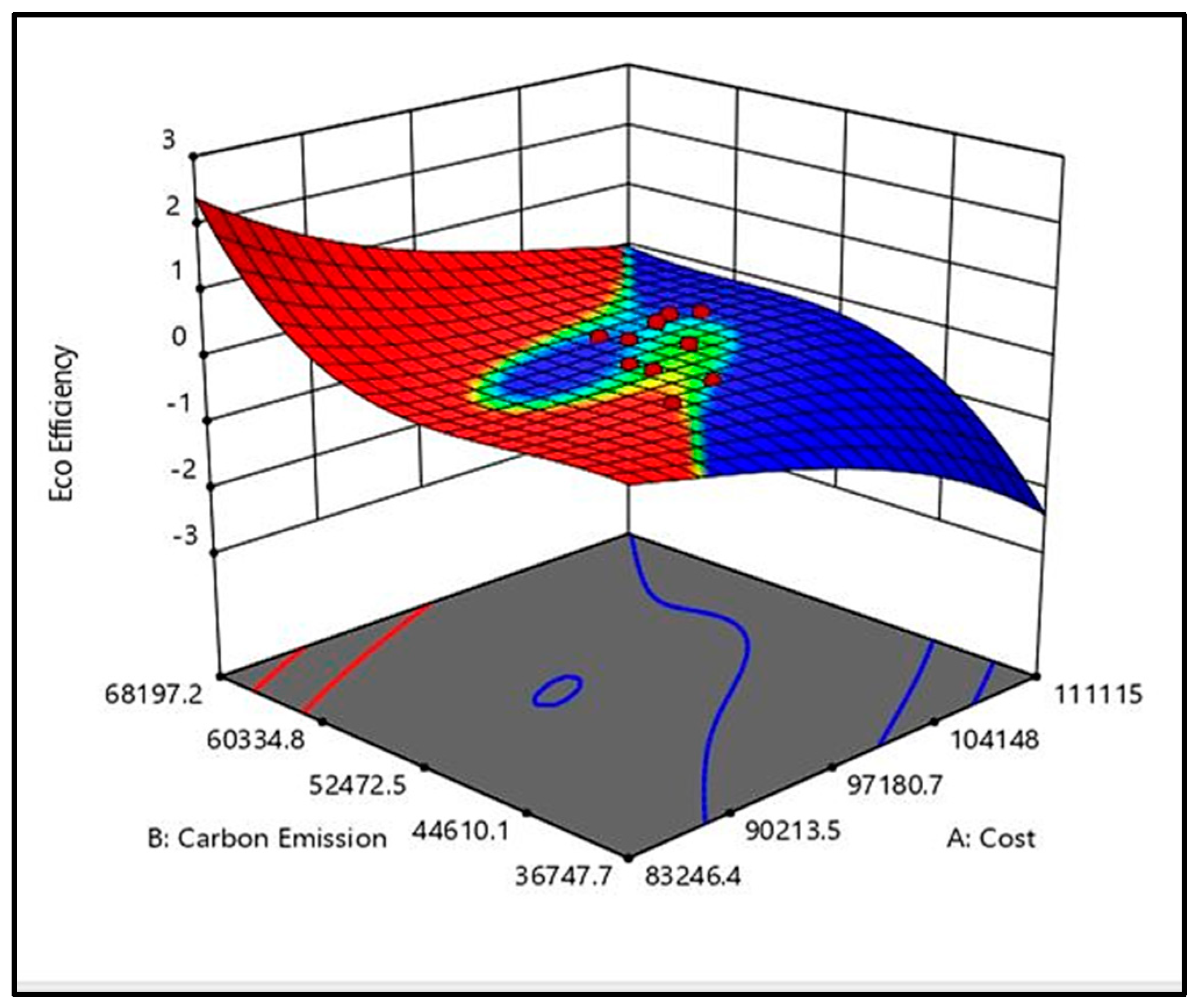

F numbers provide architects and contractors a method of determining the flatness and levelness of a concrete floor slab.

Give us a call at 224 699 9000 for details.

The most effective reference tool for determining concrete surface profiles is the molded rubber comparator chips available from the international concrete repair institute.

Velocity versus time graph of a ball of mass 50 g rolling on a concrete floor is shown in the figure below.

For floor coatings in industrial or commercial applications.

They are calculated using the standards set forth in astm e1155 which is the standard test method for determining f f floor flatness and f l floor levelness numbers the american concrete institute indicates acceptable ranges for flatness and levelness in aci 302 1 guide.

0 05 n this question is part of force and laws of motion.